Agility Trailer Brake Controller: A Comprehensive Guide

Hopkins Agility offers proportional brake control designed for safe and efficient towing, simplifying the experience through innovation and valuable solutions for all users.

Agility brake controllers represent a significant advancement in trailer braking technology, offering a user-friendly and effective solution for safe towing. Hopkins Manufacturing Corporation designed this system to simplify the towing experience, focusing on innovation and value. The Agility controller is a proportional brake control, meaning it applies the trailer brakes in proportion to the vehicle’s braking – a crucial feature for maintaining stability and control.

Installation is streamlined, often utilizing vehicle-specific T-connector wiring harnesses like those from Tekonsha, and the controller’s flexible mounting options ensure convenient access. More than 40% of retail category sales are generated from Hopkins innovations, demonstrating their commitment to quality and performance in the towing industry.

What is Proportional Brake Control?

Proportional brake control is a sophisticated system that synchronizes the trailer’s brakes with the towing vehicle’s braking action. Unlike traditional systems that apply brakes at a fixed rate, proportional control adjusts the trailer brake force based on the intensity of the vehicle’s brake pedal application. This means lighter braking on the vehicle results in lighter braking on the trailer, and harder braking triggers a stronger response.

Agility controllers utilize this technology to deliver smoother, more controlled stops, enhancing stability and reducing the risk of sway. This system ensures a more natural and intuitive towing experience, improving safety and confidence for drivers. It’s a key feature for efficient and secure trailer braking.

Benefits of Using an Agility Brake Controller

Employing an Agility brake controller delivers numerous advantages for safer and more controlled towing. The proportional braking system enhances stability, minimizing trailer sway and promoting a more confident driving experience. Installation is simplified with compatible wiring harnesses like the Tekonsha T-connector, streamlining the setup process for many vehicles.

Furthermore, the flexible mounting options allow for convenient placement within reach of the driver. Hopkins prioritizes innovation and value, making towing simpler and more rewarding. With over 40% of retail sales stemming from their innovations, Agility controllers offer a reliable and efficient braking solution for various towing needs.

Installation Process

The Hopkins Agility installation involves connecting to function wires under the dash, utilizing a T-connector harness and a simple plug-in adapter for ease.

Required Tools and Materials

Successfully installing the Hopkins Agility Trailer Brake Controller requires a few essential tools and materials to ensure a secure and functional setup. You’ll need basic hand tools like screwdrivers (Phillips and flathead), wire strippers, and pliers for connecting the wiring harness.

A multimeter is highly recommended for testing wire connections and verifying power. The Tekonsha T-connector vehicle wiring harness, specifically designed for your vehicle, is crucial for plug-and-play compatibility. Don’t forget the Hopkins simple plug-in brake controller adapter.

Additionally, you may need zip ties for neat cable management, electrical tape for insulating connections, and potentially a drill with appropriate bits for mounting the controller itself. Always consult your vehicle’s owner’s manual for fuse locations and specifications.

Wiring Harness Compatibility (Tekonsha T-Connector)

Utilizing a Tekonsha T-connector wiring harness significantly simplifies the installation process of the Hopkins Agility Brake Controller. These harnesses are vehicle-specific, plugging directly into your existing factory wiring without the need for cutting or splicing. This ensures a clean and reliable connection, maintaining your vehicle’s warranty.

The T-connector bypasses the factory brake controller wiring, providing dedicated connections for the Agility controller’s function wires. It typically includes connections for the brake pedal input, ground, and trailer electric brake wires.

Ensure the T-connector is specifically designed for your vehicle’s year, make, and model for optimal compatibility. Proper installation involves securely connecting the T-connector and then matching the wires to the Agility controller.

Connecting the Agility Controller to the Vehicle

After securing the controller in your desired location, the next step involves connecting it to the vehicle’s wiring. This is typically achieved using the wires from the Tekonsha T-connector or by directly tapping into the vehicle’s wiring harness if a T-connector isn’t used.

Carefully route the wires from the controller to the connection point under the dash, ensuring they are secured and protected from moving parts or sharp edges. Proper wire management prevents damage and ensures a reliable connection.

Double-check all connections before proceeding, verifying that each wire is securely fastened and properly insulated. A secure connection is crucial for the controller’s functionality and safety.

Identifying and Connecting the Key Wires

Successful installation hinges on correctly identifying and connecting the essential wires. The red wire serves as the brake pedal input, signaling the controller when the brakes are applied. Ensure a secure connection to the vehicle’s brake light circuit. The white wire establishes the ground connection, vital for completing the electrical circuit; connect it to a clean, unpainted metal surface on the vehicle’s frame.

Finally, the blue wire transmits the signal to the trailer’s electric brakes. Connect this wire to the corresponding blue wire within the trailer connector. Verify all connections are firm and insulated to prevent shorts or malfunctions.

Red Wire: Brake Pedal Input

The red wire is crucial as it functions as the input, directly communicating brake pedal activation to the Agility controller. This wire needs a solid connection to the vehicle’s brake light circuit, effectively informing the controller when braking is initiated. A faulty connection here will prevent the controller from functioning correctly, compromising trailer braking performance.

Inspect the red wire connection meticulously; if issues arise, re-secure it. A blown CHMSL (Center High Mount Stop Light) or stop light fuse can also disrupt this signal. Consult your vehicle’s owner’s manual to locate and check the relevant fuse. Proper functionality of this wire is paramount for safe towing.

White Wire: Ground Connection

The white wire establishes the essential ground connection for the Agility brake controller, linking it to the vehicle’s negative battery terminal. This connection is fundamental for completing the electrical circuit and ensuring the controller operates reliably. A poor or loose ground can lead to erratic behavior, inaccurate readings, or complete controller failure.

Ensure the white wire is securely fastened to a clean, unpainted metal surface on the vehicle’s frame. Verify a strong connection to provide a stable electrical path. A solid ground is critical for the controller’s performance and prevents electrical interference, guaranteeing consistent and dependable braking control during towing operations.

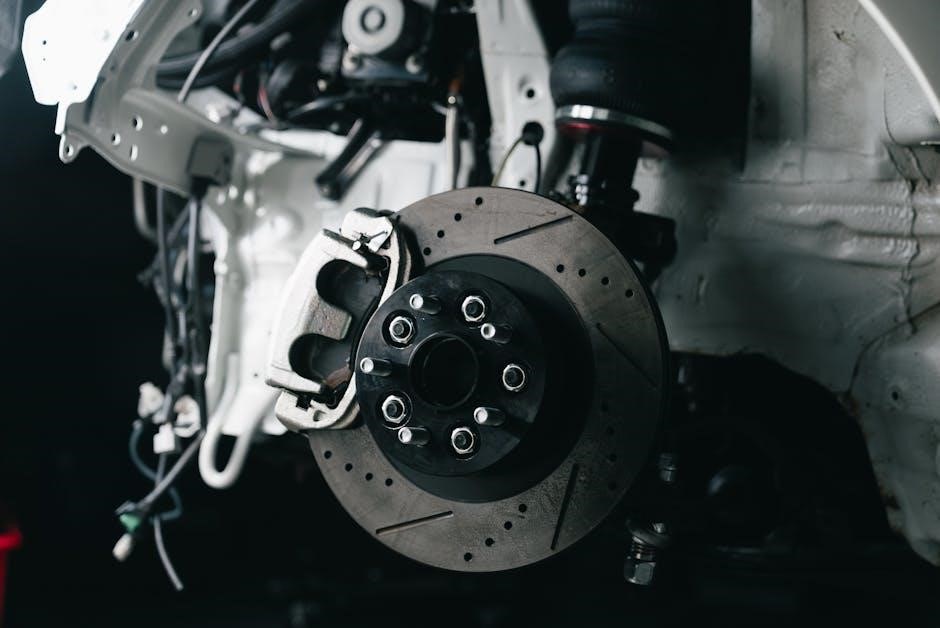

Blue Wire: Trailer Electric Brakes

The blue wire serves as the dedicated connection point for the trailer’s electric brakes. This wire transmits the signal from the Agility controller to activate the trailer brakes, providing essential stopping power during towing. Proper connection is paramount for safe and effective braking performance, ensuring synchronized braking between the tow vehicle and the trailer.

Connect the blue wire directly to the trailer brake wire, typically found within the seven-way connector. Verify a secure and insulated connection to prevent shorts or signal loss. A reliable connection ensures the trailer brakes respond promptly and consistently to commands from the controller, enhancing overall towing safety and control.

Operation and Settings

The Agility controller features a user-friendly display allowing adjustment of brake sensitivity and power, alongside a manual override function for enhanced control.

Understanding the Controller’s Display

The Agility brake controller’s display provides crucial feedback regarding braking performance and system status. While specific details vary by model, understanding the core indicators is essential for safe towing. The display typically shows the current brake power level, indicating the amount of force being applied to the trailer brakes.

A red dot, often located on the bottom right, signifies proper directional orientation during installation. The controller’s functionality relies on accurate positioning, ranging from -20 to 70 degrees nose down. Monitoring the display allows drivers to quickly assess if the system is operating correctly and make necessary adjustments to sensitivity and power, ensuring optimal braking performance for varying load conditions and road situations.

Adjusting Brake Sensitivity and Power

Agility brake controllers allow for precise adjustments to both sensitivity and power, tailoring the braking response to your specific trailer and load. Begin by setting the sensitivity, which determines how quickly the controller reacts to your vehicle’s brake pedal. Higher sensitivity means quicker response, ideal for lighter loads;

Next, adjust the power level to match the trailer’s braking capacity. Start with a lower setting and gradually increase it until you achieve smooth, controlled braking without trailer sway. Regularly monitor the display and adjust as needed based on road conditions and load weight. Proper adjustment ensures safe and efficient towing, maximizing braking performance and minimizing stopping distances.

Manual Override Functionality

Agility brake controllers feature a manual override, providing drivers with independent control over the trailer brakes. This function is crucial in emergency situations or when navigating challenging terrain. By pressing and holding the manual override button, you can apply the trailer brakes directly, regardless of the vehicle’s braking status.

This allows for corrective action during loss of control or when descending steep grades. Release the button to return to proportional braking. Familiarize yourself with the override’s location and operation before towing. It’s a vital safety feature offering an extra layer of control and confidence on the road, ensuring a secure towing experience.

Troubleshooting Common Issues

Agility controllers may fail to respond or activate brakes if wiring is faulty, fuses are blown, or the unit is outside its optimal mounting angle.

Controller Not Responding

If your Agility brake controller isn’t responding, begin by thoroughly checking the red wire connection, as this input wire signals brake pedal activation. A loose or disconnected red wire prevents the controller from recognizing braking input.

Additionally, investigate the vehicle’s fuse box; a blown CHMSL (Center High Mount Stop Light) or stop light fuse can disable the controller. Consult your vehicle owner’s manual to locate the correct fuse.

Finally, ensure the controller is mounted within the recommended operating angle – between -20 and 70 degrees nose down. An incorrect mounting angle can disrupt functionality. Verify all connections and consult the installation guide for detailed troubleshooting steps.

Brakes Not Activating

If the trailer brakes aren’t activating despite the controller displaying activity, first confirm the blue wire connection to the trailer electric brakes is secure and functioning correctly. A faulty connection here will prevent power from reaching the trailer brakes.

Double-check the ground connection (white wire) to ensure a solid electrical path. A poor ground can significantly impede brake performance. Also, revisit the red wire connection; if the controller doesn’t consistently detect brake pedal input, it won’t activate the trailer brakes.

Inspect the trailer brake wiring for any damage or corrosion. A thorough check of the entire system is crucial for proper operation.

Fuse Check and CHMSL Issues

If the controller isn’t responding, or the trailer brakes are malfunctioning, a blown fuse is a common culprit. Consult your vehicle’s owner’s manual to locate the fuse responsible for the CHMSL (Center High Mount Stop Light) and the trailer brake circuit. Replace any blown fuses with ones of the correct amperage.

A malfunctioning CHMSL can also prevent the brake controller from operating correctly, as it relies on the stop light signal to activate. Verify the CHMSL is illuminating brightly when the brake pedal is pressed.

If the CHMSL is dim or not working, address that issue before troubleshooting the brake controller further.

Mounting and Positioning

The Agility controller should be mounted between -20 to 70 degrees, nose down, ensuring it’s within reach for manual adjustments during your towing journey.

Optimal Mounting Angle (-20 to 70 Degrees)

Achieving the correct mounting angle is crucial for the Hopkins Agility brake controller’s performance. The controller functions best when positioned between -20 degrees (nose down) and 70 degrees. This range ensures the internal sensors accurately detect the vehicle’s deceleration and apply the appropriate braking force to the trailer.

If the controller is mounted outside this recommended angle, it may not operate correctly, potentially leading to insufficient or excessive braking. Always consult the installation instructions to verify the angle using a level or angle finder. Proper positioning guarantees optimal control and a safer towing experience, allowing for responsive and reliable braking in various driving conditions.